ESCODISC DLC SERIES COUPLINGS

CHARACTERISTICS OF THE ESCODISC DLC SERIES COUPLINGS

Single disc version

Torque up to 1,600 Nm

Bore up to 105 mm

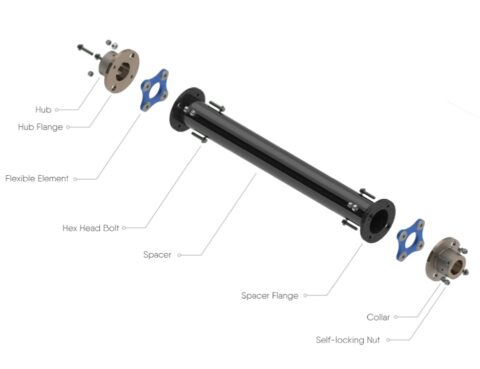

Disc couplings are of an all-metal, non-lubricated design and are torsionally stiff. The torque is transmitted by means of discs, which are alternatively mounted (on the same bolt circle) to the drive and driven flange of the disc pack assembly.

The misalignment capacity depends on the pack thickness, the disc material, the amount of drive bolts and the free span of the material between the drive bolts.

The total torque capacity depends on the disc pack thickness, total number of drive bolts and their bolt circle.

Disc couplings will in most cases have two flexible elements and a spacer. As all parts are positively connected, this disc coupling ensures good inherent balancing properties and is hence often used at motor speeds without additional balancing. Escodisc couplings meet the API 610 standards.

The Escodisc DLC series is built for infinite life and to meet the demands of the market for efficiency, lower maintenance and reduced life cycle costs. They are designed for low to medium torque/speed/duty applications (up to 1,600 Nm) where a maintenance-free coupling is preferred.

THE ESCO ADVANTAGE

The Escodisc DLC series offers:

- A single disc concept of optimized shape

- A simplified design

- The most economical solution

Alike the other Escodisc couplings, the Escodisc DLC series also offers:

- Optimized shaped stainless-steel disc for equal load distribution

- AISI 301 Full hard stainless-steel discs

- Special plated hardware

- Precisely drilled and reamed flange holes

- Black oxyded overall steel parts, oiled for protection

- Maintenance free

- Very low and predictable reaction forces on associated equipment

- No disc buckling, no fretting corrosion

- Adjustable spacer design for easy accommodating DBSE changes

- Temperature range -40°C to 270°C

- No problems in dirty and corrosive environments due to the use of stainless steel disc and protected bolts