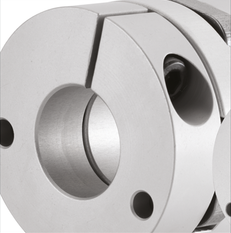

Schmidt-Kupplung Spinplus

Light and slim, it is the ideal precision coupling for highly dynamic applications. Whether it is precisely positioned, assembled or measured – this lightweight is ideal in any situation.

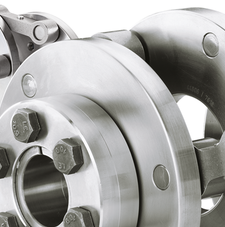

Lowest mass moment of inertia and extremely compact

When developing the Spinplus, the focus was placed on achieving the lowest possible mass moment of inertia for the coupling.

This was achieved thanks to the unique function element manufactured through the modern MIM process, which allows universal displacement compensation on one level. As a result, the technical advantage lies in the very compact design of the coupling and high power density, combined with a minimised mass moment of inertia. This makes it ideal for highly dynamic and increasingly energy-efficient drive solutions.

Precise, torsionally stiff and backlash-free

In the design of the FEM-optimised function element, the focus was placed on optimal weighting from high torque transmission, maximum torsional rigidity and universal displacement capacity.

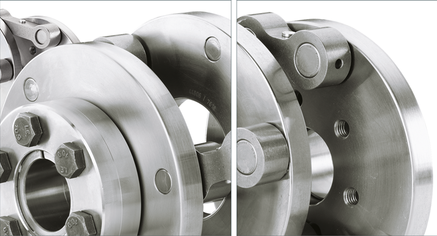

Innovative hub design – optimised mass moment of inertia

In addition to the coupling design, which already has an optimised mass moment of inertia, the newly developed and innovative hub design highlights further optimisation of the lowest mass moment of inertia concept. These clamp hubs reduce the mass moment of inertia significantly compared to conventional hubs.

To adapt to the respective application requirements, two hub versions have therefore been designed. Version A provides the lowest possible mass moment of inertia, Version B is designed to accommodate large shaft diameters and focuses on the most compact dimensions.

> Fields of applications

Spinplus application fields include:

· Highly-dynamic servo motors

· Handling and automation technology

· Robotics

· Stepper motors

· High-resolution measurement technology and much more