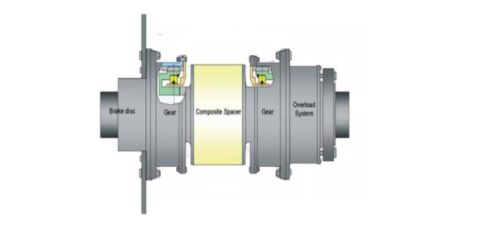

ESCOGEAR HIGH-SPEED SERIES GEAR COUPLINGS

CHARACTERISTICS OF THE ESCOGEAR HIGH-SPEED SERIES COUPLINGS

Multicrown gearing version

Application-wise customized with weight-optimized flanges and hubs

Oil or grease lubricated

Balanced for high rotation speed up to 20,000rpm

The Escogear High-Speed series couplings are lubricated type couplings, also called high-performance gear couplings. Used in high-power/ high-speed applications, they incorporate specific and high-precision gear geometrics as well as a dedicated cooling / lubrication system based on grease or oil to allow for long continuous running periods without maintenance.

The couplings design may differ as a function of the application and the characteristics of machines to be connected and hence full data are required for coupling design.

The gearing parts are generally made out of forged high-alloy steel and gears are surface hardened and mostly nitrided. Balancing is required, as well as compliance with API 671. These couplings generally operate at high temperatures and thus require special provisions for thermal expansion of the machinery elements in line with the basic features of the couplings.

The Escogear High-Speed series is robust and reliable. It meets the specific requirements of the various rotating machines in the medium and heavy industries.

THE ESCO ADVANTAGE

The Escogear High-Speed series offers:

- High torque capacity for required angular misalignment, allowing the coupling to operate under combined load, speed and misalignment conditions

- Surface hardened teeth (nitriding)

- High bore capacity

- High alloy components and light weight

- The highest manufacturing quality and long coupling life guarantee

- A Multicrown gear shape allowing optimized gearing surface contact and numbers of gears contacting

- Perfect homokinetic torque transmission

- Reduced backlash

- Specific gear top centering

- Oil (injection batch or tooth by tooth) or grease lubrication

- Component balancing (assembly balance check; optional)

- ISO 9001 certification