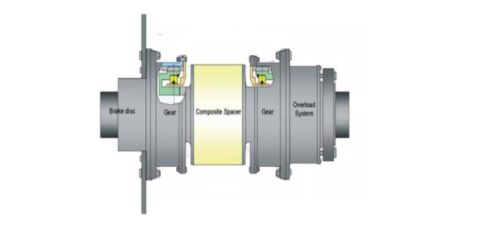

ESCOGEAR C & C-M – SERIES COUPLINGS

CHARACTERISTICS OF THE ESCOGEAR C & C-M SERIES COUPLINGS

Multicrown gearing with continuous sleeve design

Torque up to 348,000 Nm+

Bore up to 290 mm+

The ESCOGEAR C & C-M – SERIES COUPLINGS couplings are torsionally rigid grease filled couplings consisting of two hubs with external crowned – and one single sleeve with two pairs of straight internal teeth on each sleeve end, a so-called continuous sleeve. Both sleeve ends are sealed. These are the most compact gear coupling designs.The teeth of hub and sleeve are continuously in contact with each other and have been designed with the necessary backlash to accommodate angular-, parallel- and axial misalignment within their misalignment capacity. The angular and parallel misalignment capacity is determined by the gear tooth design and is for the standard Escogear max. 1.5° degrees (2 x 0.75°) in total. The axial misalignment capacity is limited by the gear teeth length in the sleeve and can be varied (optionally – for C…M series only).Gear couplings are generally made from carbon steel Ck45 (AISI 1040). For higher torque capacities, within the same coupling dimensions, a higher alloy steel as 42CrMo4QT can be used (optionally).The Escogear C & C…M series are substantially lighter in weight than the Escogear F-series. These compact designs make the Escogear C & C…M series ideal for use in applications where space is limited and weight is important. Two versions are available. The CST for bores up to 110 mm and the CST…M configuration for larger bores.

THE ESCO ADVANTAGE

The Escogear C series offers:

- High torque capacity & significant angular misalignment allowing the coupling to operate under combined load, speed and misalignment conditions

- Easy coupling selection

- High bore capacity

- Light weight

- A high manufacturing quality

- Long guaranteed coupling life

- Multicrown tooth form

- Perfect homokinetic torque transmission

- Less backlash compared with conventional or circular tooth forms

- Perfect gear top centering

- Excellent corrosion protection of components