ESCOGEAR FWMO VARIANT COUPLING

CHARACTERISTICS OF THE ESCOGEAR FWMO VARIANT COUPLING

Multicrown gearing optimized for wind mill applications

Accommodating misalignment combinations up to 2 (4) degrees

Torque up to 260,000 Nm

Bore up to 240 mm

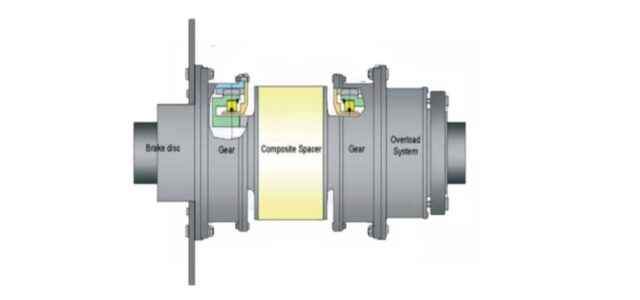

Gear couplings are lubricated type couplings with the highest torque capacity. The Escogear FWMO series couplings basically consist out of 2 rigid hubs maintained on the machines shafts and a floating spool spacer incorporating the gear coupling.

Gear couplings in general accommodate angular and axial misalignments. Where the angular misalignment is determined by the gearing geometry, the axial capacity varies according to the manufacturer and can be large depending on the application.

The possibility of selecting a specific gearing configuration enables specific challenges to be met.

For wind turbine applications, the gear couplings having larger misalignment capacity, can be quite short hence complying with steady-state requirements. The coupling may include brake discs, electric insulating or overload protection provision.

The Escogear FWMO variant for wind turbines was developed especially to meet the highest demands of the wind industry. It permits the operator to benefit from maximum and continuous energy production, avoiding stoppages due to irregularities in the grid, according to the latest E-ON directives.

THE ESCO ADVANTAGE

The Escogear FWMO variant offers:

- Easy installation, compact, light and maintenance-friendly design

- Perfect homokinetic torque transmission

- High misalignment capacity (up to 4°) and high balance quality

- Low vibration levels

- Electric insulation

- Specific surface protection (optional)

- The ESCO’s EIOS Overload Protection System/Torque Limiter (optional)