Grid couplings

Resilient Coupling comprises mainly two hubs, Grid Spring and Cover to protect the spring to fly off to centrifugal force and to prevent Grease to come out. Grid Spring element is so designed that it provides resiliency for variable flexibility of a Coupling and damping properties making the Coupling very for drives involving high shock loads to the extent of 80%.

Misalignment – Angular, Parallel or Axial, that inevitably occurs between rotating shafts, which are independently supported, is also taken care of by the spring element within allowable limits

Features

- All Metal Construction having no fast wearing out components

- Torsionally flexible Transmit full torque with dampened vibration and deduced peak load.

- Accommodates angular, parallel and axial misalignment.

- High ratings.

- Versatile design and interchangeability

- Easy assembly and maintenance

- Very low Downtime.

- Longer service life.

Range of Resilient Couplings

- Standard Couplings with vertically split cover.

- Standard Couplings with axially split cover.

- Flanged Couplings with vertically split cover.

- Flanged Couplings with axially split cover.

- Brake Drum couplings.

- Spacer type couplings.

What is the difference between Horizontal and Vertical Grid Couplings?

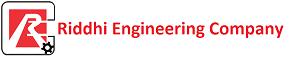

Horizontal Split Cover Grid Coupling

The difference between “horizontal” and “vertical” grid couplings lies simply in two types of split cover designs (and their corresponding cover kits). The grid spring elements and coupling hub technology are the same.

Horizontal covers are designed for ease of assembly and removal, particularly in tight spaces, as they can be put on after the hubs and grid spring element have been already assembled.

Horizontal Split Cover Grid Coupling

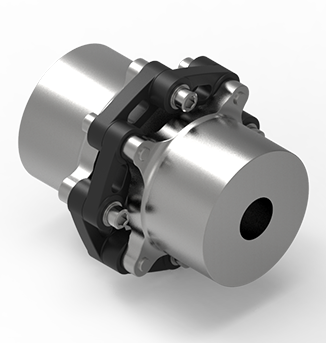

Vertical split cover designs require putting the split covers on the shaft prior to putting on the shaft hubs and grid spring element. Once the hubs and grid spring element have been attached, the vertical split covers can then slid over the hubs and grid spring element and fastened together. (This also means that to completely remove a vertical split cover off a shaft, the grid spring element and coupling hubs would have to first be removed.)

The benefit of the vertical split cover design is that it can operate at a higher maximum speed (RPMs).. Based on your application, it may be required to go to a vertical split cover design if the horizontal cover design maximum speed is too low.